Quick read in Bold;

Refer to other sources on internet to be sure, that any classic diesel engine does run well and same-same on any, cheap veg oil. Did you know — the first diesel engine ran on peanut oil? Ask Wiki. I’m not here to convince (again!) anybody that it works. No difference at all, but one little condition to keep in mind (for peace of mind) — pure oil should be used when engine is hot (preheated).

How does it work?

To start a cold engine only using veg oil is quite a complicated matter, although possible. It’s a matter of conditions (temperature, compression) and chance. That is why, diesel is needed to start/stop the car.

First, start the engine using diesel and drive until engine’s temperature rises up to approx 50-70’C, then switch to oil. Best Before parking, switch on to diesel again (give a bit of a run). This will refill compartments such as pump, pipes and fuel-filter back with diesel for the next ignition. No need to bother if you are stopping for 30-45 minutes (either hot summertime), as engine will still remain hot and will start normally on oil.

Pros and cons:

- today (May’19), difference between oil price in supermarket and next-door petrol station diesel, is 30% (0.98/l v.s. 1.35/l); Cheap veg oil price has not changed since five years (approx 1€); Comercial, 25l oil barrels cost 0.88/l (sunflower).

- to run on veg.oil it is illegal as you don’t pay certain taxes;

- burnt veg.oil smells like fries and does not pollute environment as badly as diesel;

- oil is thicker than diesel, unless oil is preheated up to 60’C;

- oil tends to clog (very slow process) while in contact with air, (v.s. diesel — evaporates);

- oil — greasy business, when it comes to filling in from little bottles (find comercial, 25l cans);

- MOT (TÜV, ITV, aka technical inspection) can not be passed with such DIY system (besides, it is illegal), so keep in mind to build it in a way that is easy to remove/re-do, before going for MOT;

Dual system v.s. preheated oil system:

There is a system to run a car exceptionally only on oil, but in such case oil preheating closed circuit should be built-in (before fuel pump), as it will be inconvenient to heat up to 60’C full tank of oil . I found this bit more complicated and more expensive to build.

Things needed:

- 4 solenoid valves (normally closed), 6-8mm outlet with manual switch (usually used for vehicle gas conversions). Approx 18€ each;

- 2 brass T-connectors, 1 brass I-connector, 6mm outer;

- 3m (keep extra) fuel pipe, 6mm inner;

- Dozen of 10mm Spring Pipe Clips;

- 5l fuel tank/container for DIY with outlet (screwed separately);

- ON—ON (either on-off-on) switch, wires, terminals and possibly, one diode;

Keep in mind! Fuel pump makes constant, closed-circuit flow of fuel and it takes from the flow exact amount (by acceleration) of fuel to burn. Flow is fairly quick and flows in about 1 l a minute (when engine is accelerated, and approx ½l for neutral run).

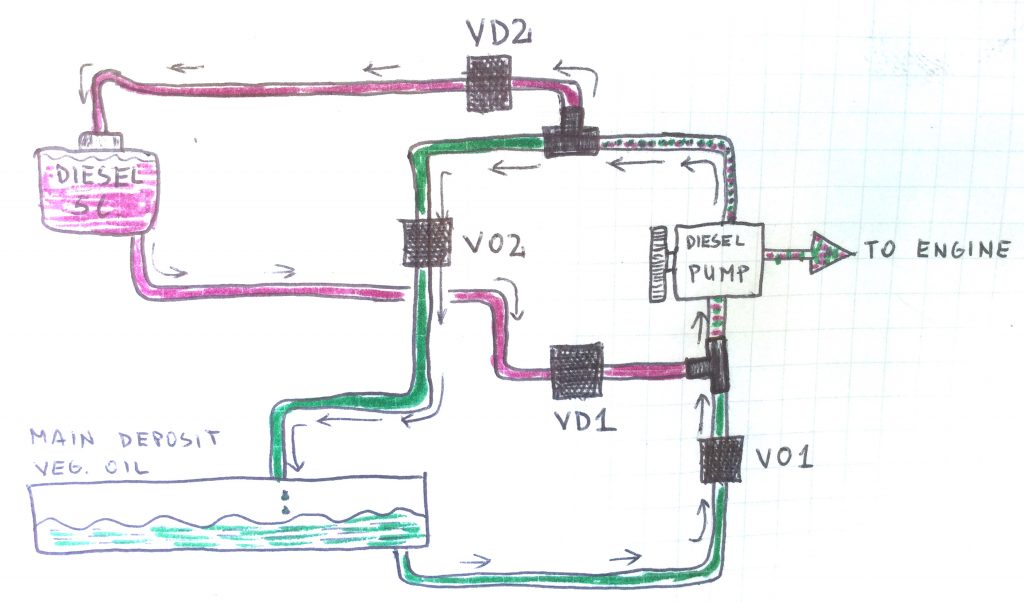

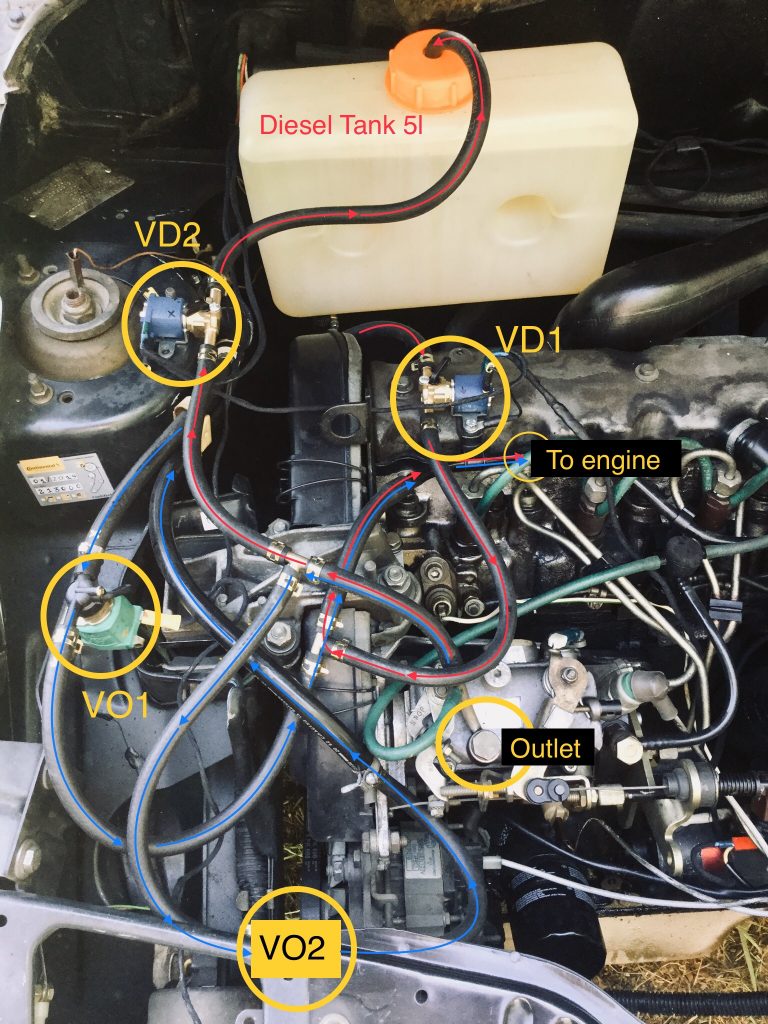

A rough scheme of two, separate closed-circuits for oil (green – original circuit) and diesel (pink – additionally built-in). VD1-2 = Valves for Diesel; VO1-2 = Valves for Oil;

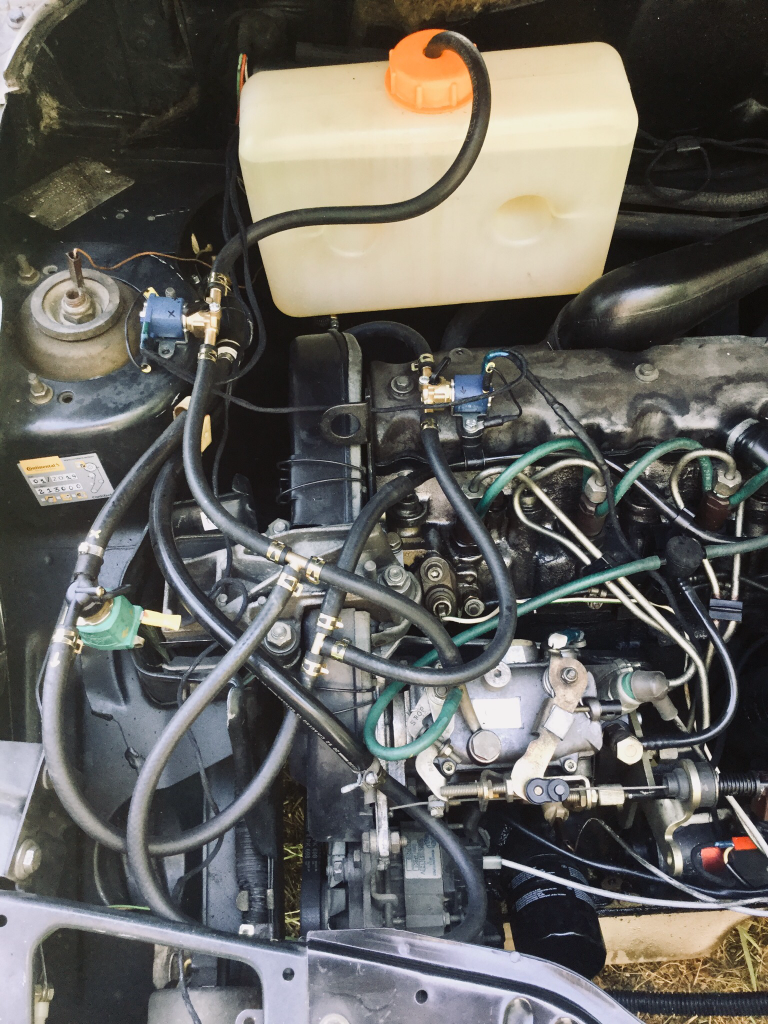

There are two, thick fuel pipes — one comes quite long way, through the fuel filter, before finding inlet in to the pump (do not bother), another pipe (outlet), is very visible and connected straight-forward to the pump and sends back fuel overflow to main deposit;

You will have to cut inlet pipe (VO1, and T-junction at the point red/blue arrows are met) before the filter and cut (either disconnect) outlet pipe closest to the pump and put T-connectors through which diesel from little tank will come. Two valves to cut oil-circuit (green; one valve [yellow square] is hidden under the panel, not visible on the pic) and two valves to cut diesel-circuit (blue). Position of valves is not so important, as once they are closed, diesel and oil won’t mix.

Wiring:

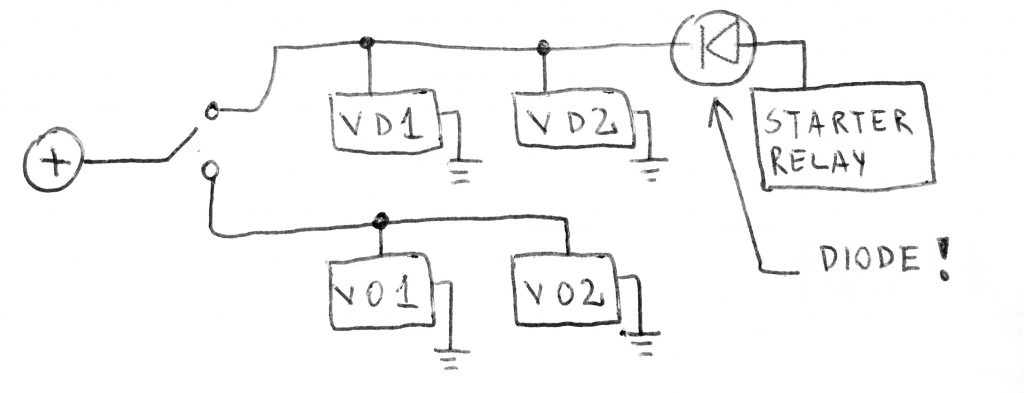

Valves normally are closed. To open valves, you have to feed the power in to them. Find the positive (+) current connection in the car’s wiring (while key is switched on) and bring it through the ON-ON switch in to one (VD1-2) and another (VO1-2) sets of valves;

Attention! Refer to one simple fact — while starting car (powering starter), whole car’s power is cut as it all dedicated to the starter only. This means, that at the starting point you might lose power in VD valves, so they will get closed and this might be a tough business for the fuel pump.

So unless you make sure this won’t happen and do other type of wiring than suggested on a scheme below. Simple alternative might be to use 3-way (ON-OFF-ON) switch wired straight in to battery wiring, but make sure you will not forget switch it OFF while car is unused, to avoid unnecessary loss of power (which will keep the pair of valves constantly opened).

To keep VD valves open at the moment of starting, I’ve pulled a wire from starter’s relay (gives 12V+ while ignition key is on). What happens next — starter’s relay is empowered from VD wiring and not by ignition key. To fix such ERROR, I’ve simply soldered diode in to wire connected between VD1 and starter’s relay, so power penetrates through it in to VD, but power in VD wiring does not flows back to starter’s relay. SOLVED.

Greasy business:

While filling in the oil with 1l or 5l bottles, use the torch-lighter and at the right point burn a little hole on the bottle to give it a smooth flow. Do not penetrate very bottom part of bottle, as placing bottles back vertically those will leak.

TBA:

observations, failures, updates, ideas. Keep an eye on this page or RSS it.

Additional ideas:

… is to use programmable relay/switch thermostat to automatically switch to oil-use, once the right temperature is reached. However, switching back to diesel must be done manually.

EDIT1: I do not bother anymore, as so far have never forgot. More often I forget to swith it back to diesel, which is not a big deal.

Switching back to diesel, some outcome oil will be mixed to diesel deposit. No worries at all, quantities are very little and never exceed 1:1 mixture before filling up it with diesel again.

Pure oil only:

Yes, but it is a lottery. Few times already I had a quite a problematic start — early morning, mountails. So depends on quite many conditions. For few weeks I was starting normally on pure oil only, but the line is thin and have to give 15-20 min of engine run, until from pulsating roaring it will reach equal run (when engine reach approx 70’C).

So far:

I have burnt approx 200l of veg-oil and some 20l of diesel. No anomalies observed*.

Dis/Assembling:

If used Spring Clips (v.s. screw-clips) disasembling takes to undo 4 screws — 2 of tank and 2 of valves; 2 T-connctors (and 1 I); all wireing goes off. It takes 10-15 min only..

Assembling back might take a bit longer. Suggestion: mark loose ends, which will help to connect it back quickly in a same order, after;

*EDIT1, after few years — old car problems and another veg.oil properties:

My car is almost 30yo and the most problems would make all rubber parts. Plastic parts serves longer, but rubber parts (mainly I refer to rubber washers, gaskets..) with time are shrinking, getting harder and cracking.

Comparing to diesel, veg.oil is more smooth, or more greasy and more slippery. This makes some rubber washers (and gaskets) to leak or worse – pop-out from it sockets.